Roof Access

When carrying out a roof safety inspection, one of the first things to consider is how convenient and safe is it for contractors and maintenance workers to access. Commercial buildings can have fixed access ladders mounted to the building’s exterior or a compact rooftop hatch. Fixed access ladders are galvanised steel vertical ladders with a frame around them for fall prevention whereas rooftop hatches are accessed from the interior. Some building managers or owners prefer rooftop hatches as aesthetically they can look more appealing than the vertical ladders attached to the side of the building.

Both rooftop hatches and vertical access ladders are safe and convenient options for accessing roofs, as well as having longevity. However, these fixtures must be still checked as part of the risk assessment for wear and tear.

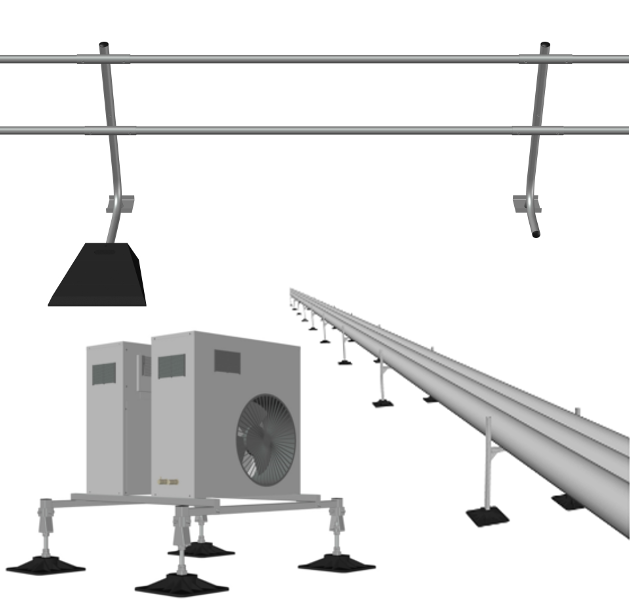

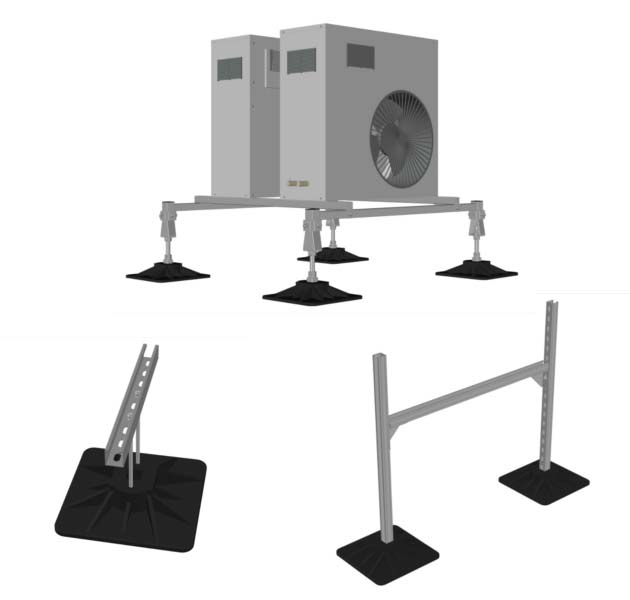

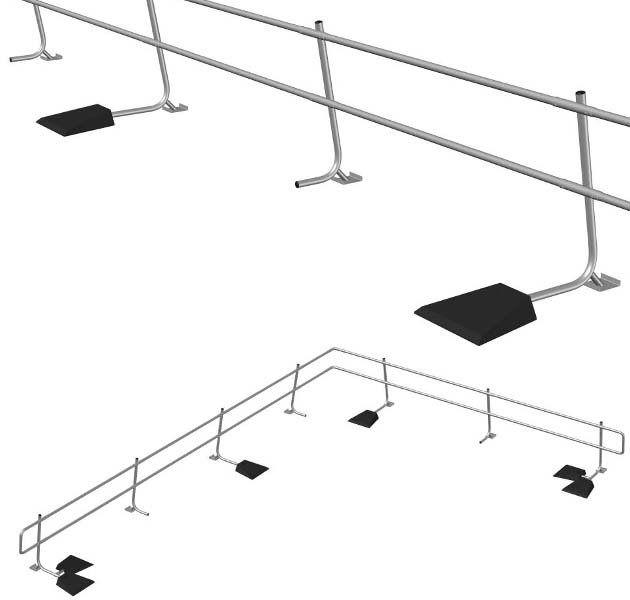

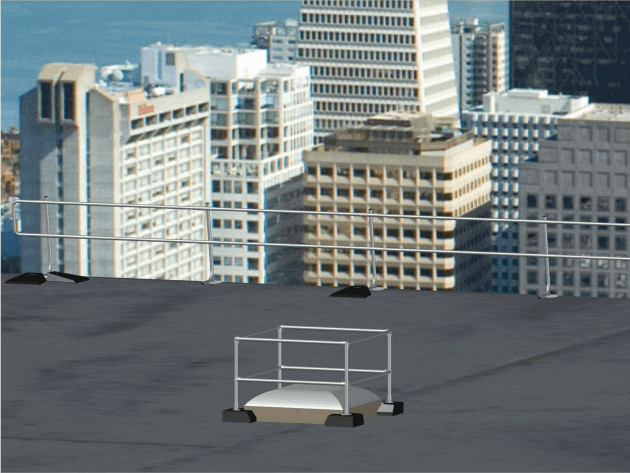

Safety Railing

Guardrails are a steel galvanised railing system and are key to increasing safety when working at height. Each roof will have specific safety requirements, but in general, the roof edge protection system is recommended to be positioned around the perimeter of the flat rooftop. Guardrails can be installed temporarily or permanently and this will depend on factors such as location and roof type.

Most guardrails available are freestanding guardrails, which means that there will be no need for alterations to the structure of the building to install the guardrails. If installed to the correct standards the guardrails should be secure enough to take enough weight to prevent falls from height.

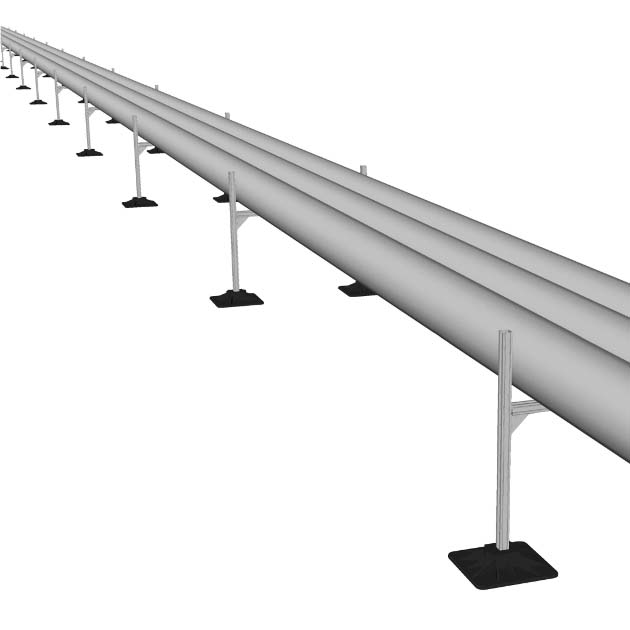

Cross Over Platforms

Navigating safely across a roof can be quite difficult, especially when there are large pipes or roof height level changes that require maintenance or for contractors to climb up or over. To eliminate these hazards, cross over platforms or access ladders are recommended to be fitted to ensure these obstacles can be safely stepped over and work can be carried out risk-free, also allowing access to areas of the roof that are hard to reach

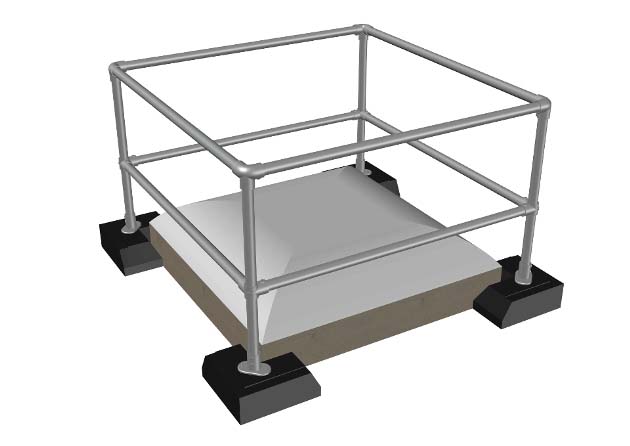

Skylights

Skylights are a hole in the roof surface and if not closed off, could be dangerous to maintenance workers or contractors. To avoid serious injury when working at height it is recommended that you should consider skylight safety with either a skylight screen or freestanding guardrails.

A skylight screen is a wired mesh that is placed over the skylight. The mesh lets enough natural light in to keep the skylight functional but helps to avoid accidents that could damage the skylight screen and injure the maintenance employee or contractor.

Freestanding guardrails around the skylight is another option to consider for enhancing skylight safety and avoiding incidents.

Rooftops can be a dangerous area to work on: not only are there the obvious dangers of falling from a height, but the hazards of slips and trips when up on the roof should be considered. By eliminating or reducing the hazards mentioned with the equipment above, contractors and maintenances employees are much safer.

To find out more about improving your roof safety procedures or to obtain further information on working at heights visit HSE or get in touch with a member of our team.