If you have any equipment on the roof of your business premises that requires regular maintenance, you need to know what's what when it comes to working at height regulations.

If you hire a contractor to maintain plant such as air conditioning units on your roof, you may think that you're not responsible for providing personal protection equipment (PPE). However, you do still need to ensure that your roof is safe for access at any time, regardless of whether you use a contracted company to maintain equipment.

Your contractor may have all of the PPE required for their staff, but you can't guarantee that it will be used. That's why permanent roof guardrail (and plant barriers/risers/step over ladders, while we're at it) are a surefire way to protect your business from litigation that arises from working at height incidents.

Working At Height: The Rules

The Work At Height Regulation 2005 covers anyone who requires people to access a high area, such as a roof, scaffold or ladder, for the purpose of maintenance or other work. That includes building owners, even if they use a contractor to carry out the work.

As a building owner, or contractor, to adhere to working at height regulations you must:

- Fully assess the work required with a view to risks and hazards

- Provide alternative options to working at height where possible

- Take measures to provide a safe environment where working at height is unavoidable

- Mitigate risk by limiting access areas near dangerous points such as fragile skylights.

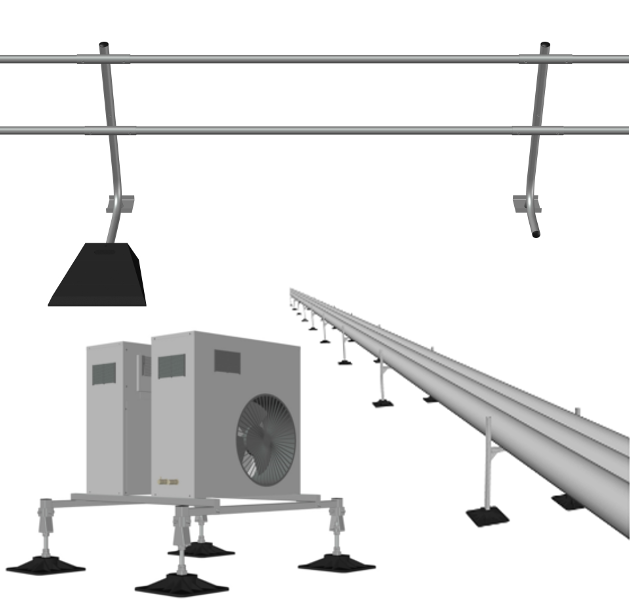

How Roof Safety Systems Ensure Compliance

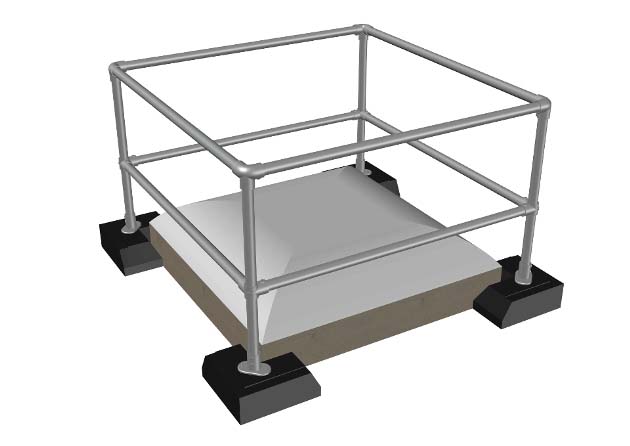

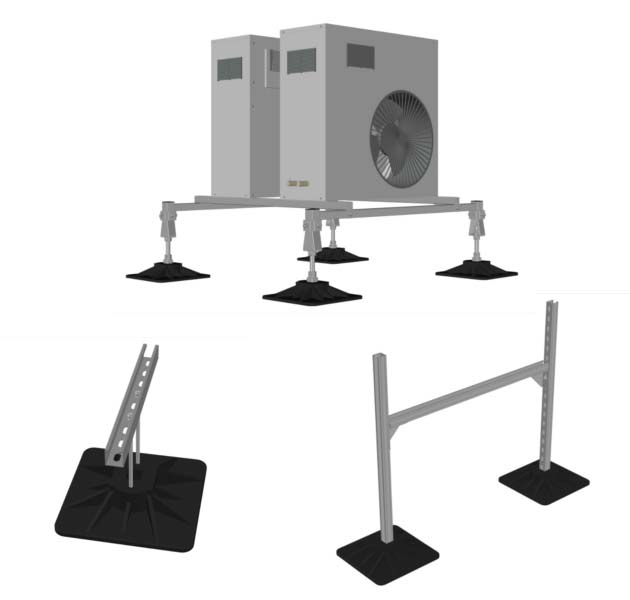

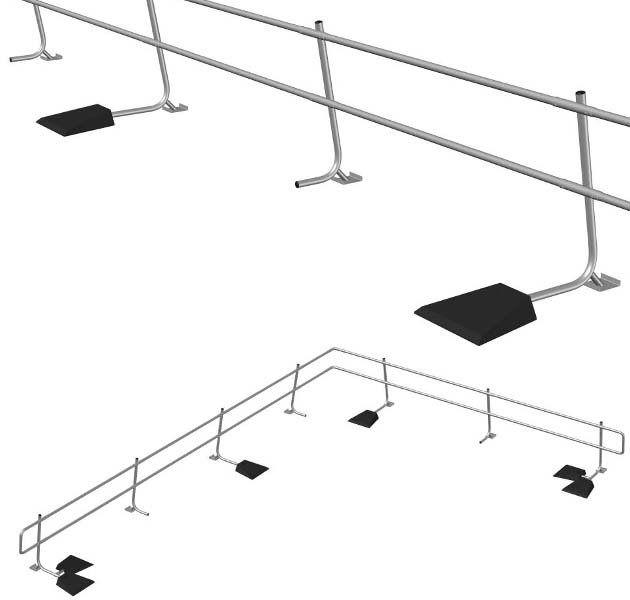

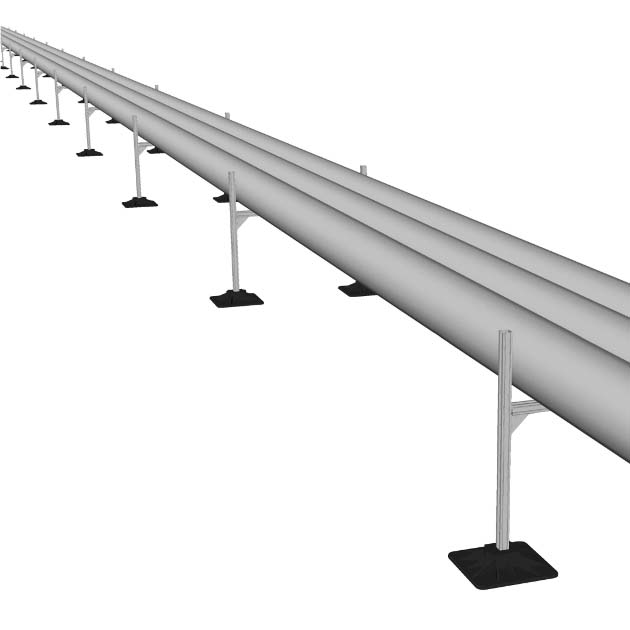

A guardrail system can be quickly and easily installed on any roof type, and freestanding rails don't even need to be fixed to the roof in order to maintain compliance. This means a faster install and no structural drilling or penetrations to the waterproofing.

Some roof areas may not be suitable for freestanding rails, but there are other options, such as railings designed to clamp or fix to parapets, or riveted systems spanning crowns on a corrugated metal roof

Some premises owners and contractors may use a safety line and harness combination, but this requires reliance on human intervention and may not be followed by a worker. A safety rail removes the requirement for any action on the part of the worker (no need to get into a harness and clip to a guide line) and provides a safe environment.

Remember Access Routes In Your Safety Plan

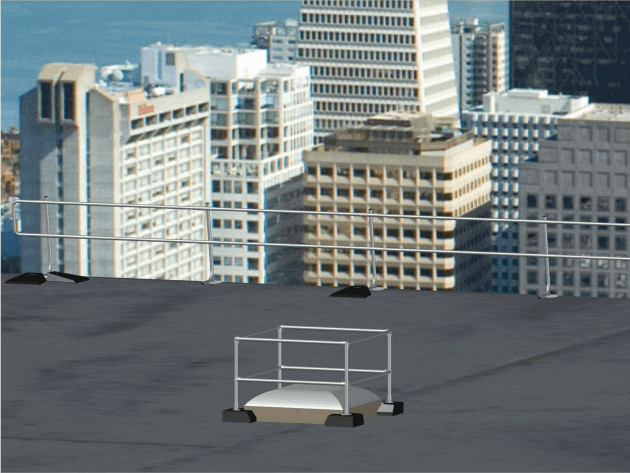

It's all very well having a rail in place once your workers are on the roof - but how do they get there? Or if your roof has structures or obstacles, how are they safely navigated? Are there any cables which could cause them to trip?

It's your responsibility to ensure workers are safe in ALL of their work - including getting to and from the area which requires maintenance.

Ladders, steps units and platforms ensure a safe and easy access route to plant which requires maintenance, such as air conditioning units. A step platform reduces the distance between the (roof) level and the plant requiring maintenance, helping you to comply with the Working At Height regulations (which stipulate mitigating fall risk by reducing distance where possible).

Are You Compliant?

If you're not sure whether your building premises are compliant with the latest Working At Height regulations, get in touch - we'll have a free no-obligation chat with you to help.