At some point in time, engineers and maintenance workers are going to require access to your business premises rooftop. Are you prepared?

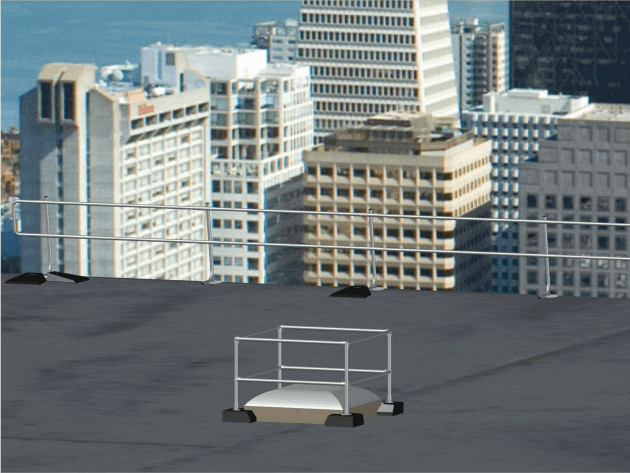

As a business owner, you have an obligation to ensure anyone working on your site is protected against risk of trips and falls - especially when working at height. That's easily done with simple additions such as a perimeter freestanding roof safety rail - but what about accessing plant, such as air conditioning units?

There are several ways to ensure plant is easy and safe to access for any engineer to perform maintenance and repairs:

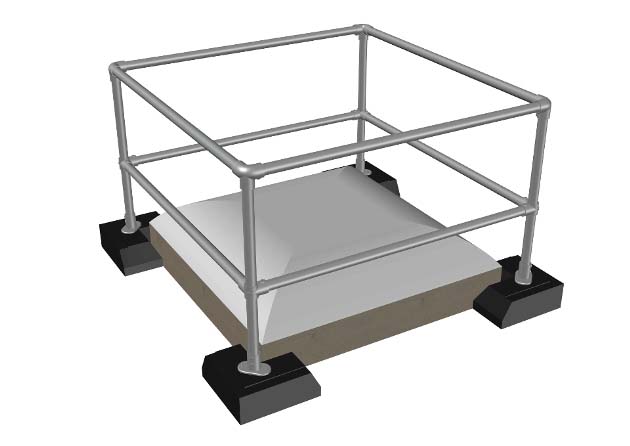

Preventing unnecessary damage to units will reduce the amount of time required to be spent on a roof observing and repairing any problems. The best way to do this is keep all plant out of reach of anyone who may access the rooftop.

A barrier, such as a freestanding Rhinorail, will prevent unnecessary access and protect units from damage. These can be fitted with spring-loaded gates that are self-closing, allowing easy deliberate access while preventing unnecessary access.

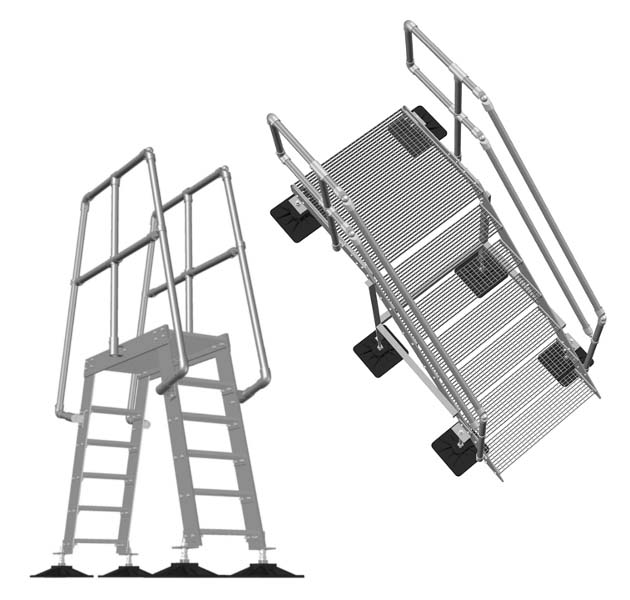

Units are often placed in hard-to-reach areas, especially on a multi-level roof. This will require any maintenance worker to navigate the ups and downs of the roof to even get to the unit.

Sometimes a vertical ladder will suffice, where the plant is placed on a tall structure. Most of the time, however, an up-and-over ladder provides additional safety when accessing different levels on the rooftop, and will enable engineers to more easily access hard-to-reach units.

Where a roof has several levels, or plant is placed in a hard-to-reach area, a step platform is a good idea to ensure access is easy without compromising on safety.

A platform allows an engineer to access any type of plant at a safe level, without the need to climb over obstacles or reach unnecessary heights.

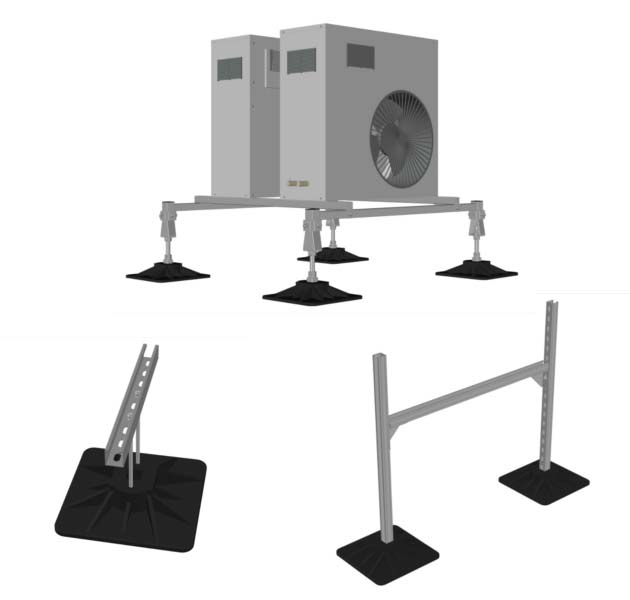

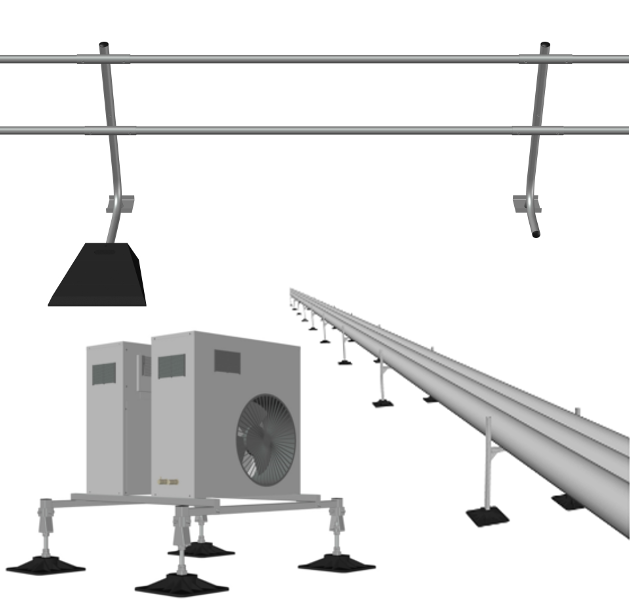

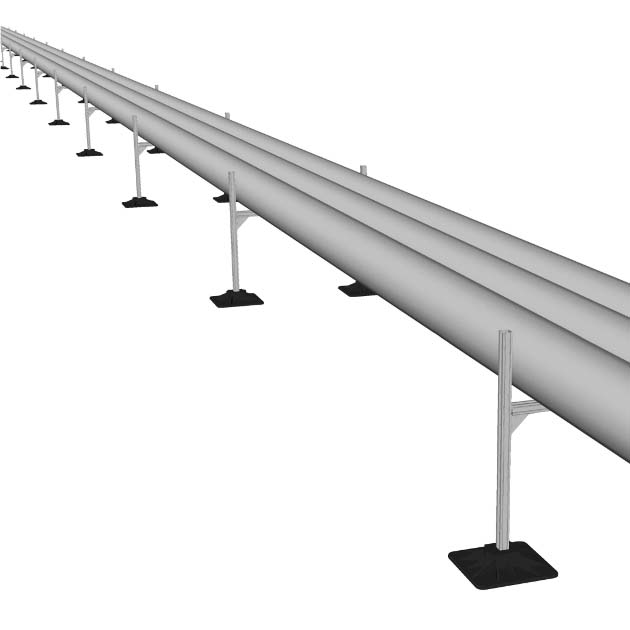

Raising units can be beneficial by increasing accessibility while also reducing the need to bend down at difficult angles to perform maintenance and repairs. A raised plant stand, like those in our Titan range will deliver stability as well as improve accessibility to all areas of the unit.

Roof safety isn't just about securing plant in place - you also need to consider the journey of the engineer across the rooftop, and any other areas or plant he may need to access.

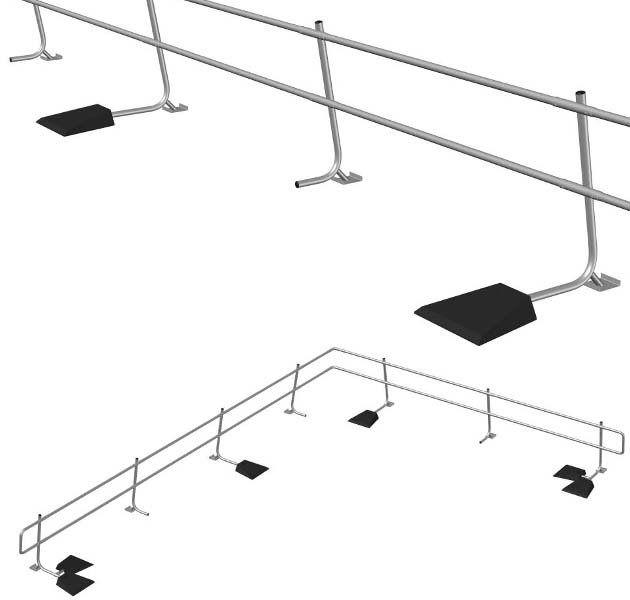

Cable ducts are a good way to improve safety: they raise cables to an easy-to-spot height, prevent potentially damaged cables sitting in water on flat rooftops, and also make it easier for an engineer to assess cables whenever required.

Get an Assessment

If you're still not sure what will make your rooftop as safe as possible for engineers to access and work with ease, get in touch. We'll help you assess the rooftop of your business premises to determine the best steps you can take to minimise risk and maximise roof safety.